SBG applies for Patent for the Condless Process

The Standardkessel Baumgarte Condless Prozess

January 2022

The Standardkessel Baumgarte Condless process is an innovative process for the utilisation of vapours / fumes produced during sewage sludge drying.

All processes available on the market so far recycle the vapours via condensers, e.g. for district heating, and return them to the sewage treatment plant. However, there are also locations that utilise sewage sludge where no district heating networks or sewage treatment plants are available. Then the Condless process can become decisive for project realisation.

The process developed by Standardkessel Baumgarte offers an economical solution for bypassing these process steps and utilising the vapours/fumes from sewage sludge drying in a thermal process.

The Condless Process in Detail

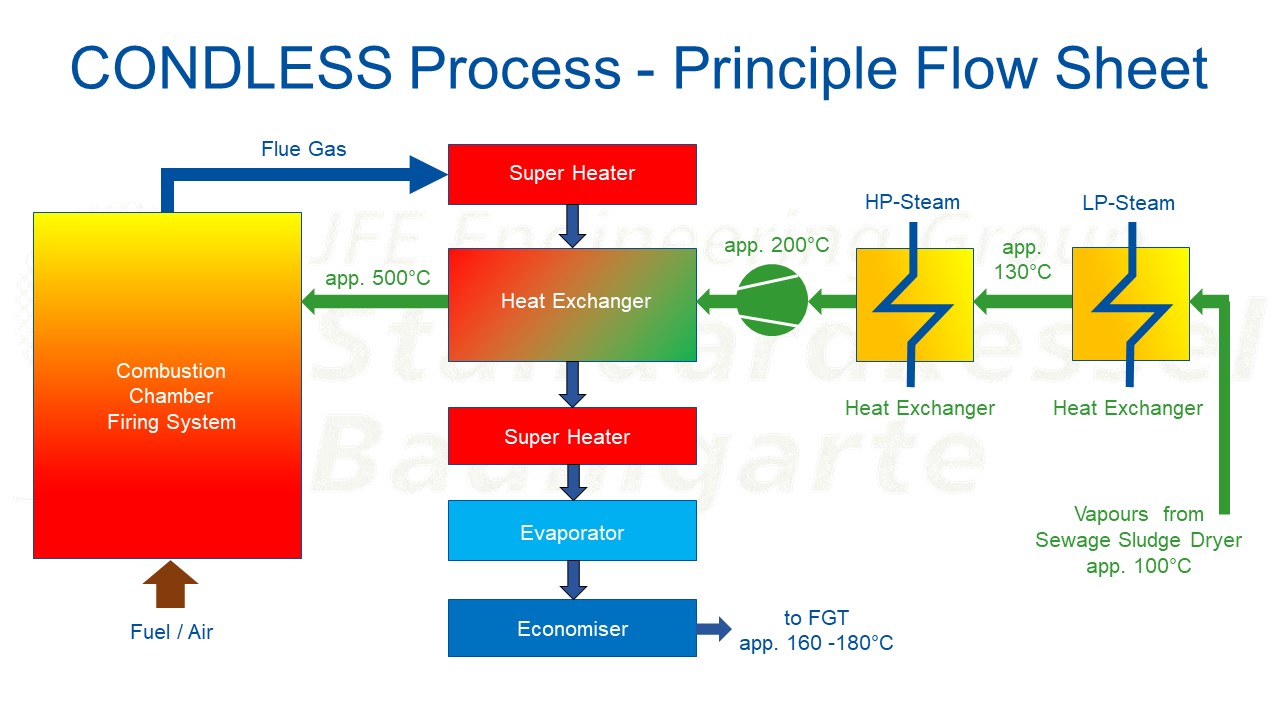

The vapours from sewage sludge drying are fed into an incinerator (e.g. fluidised bed) after being preheated in the combustion chamber. The vapours are preheated using thermal energy from the water/steam cycle and from the flue gas of the subsequent incineration process. The heated vapours are then fed to the flue gas side of the incineration plant at a temperature range of 870 - 950°C in compliance with the legal requirements. This means that the sewage sludge vapours can be utilised 100% residue-free and without expensive disposal routes. However, the ammonia contained in the vapours is not relevant in the temperature range of 850-900°C and does not make a significant contribution to denitrification.

Condless-Process – Principle Flow Sheet