THE TASK

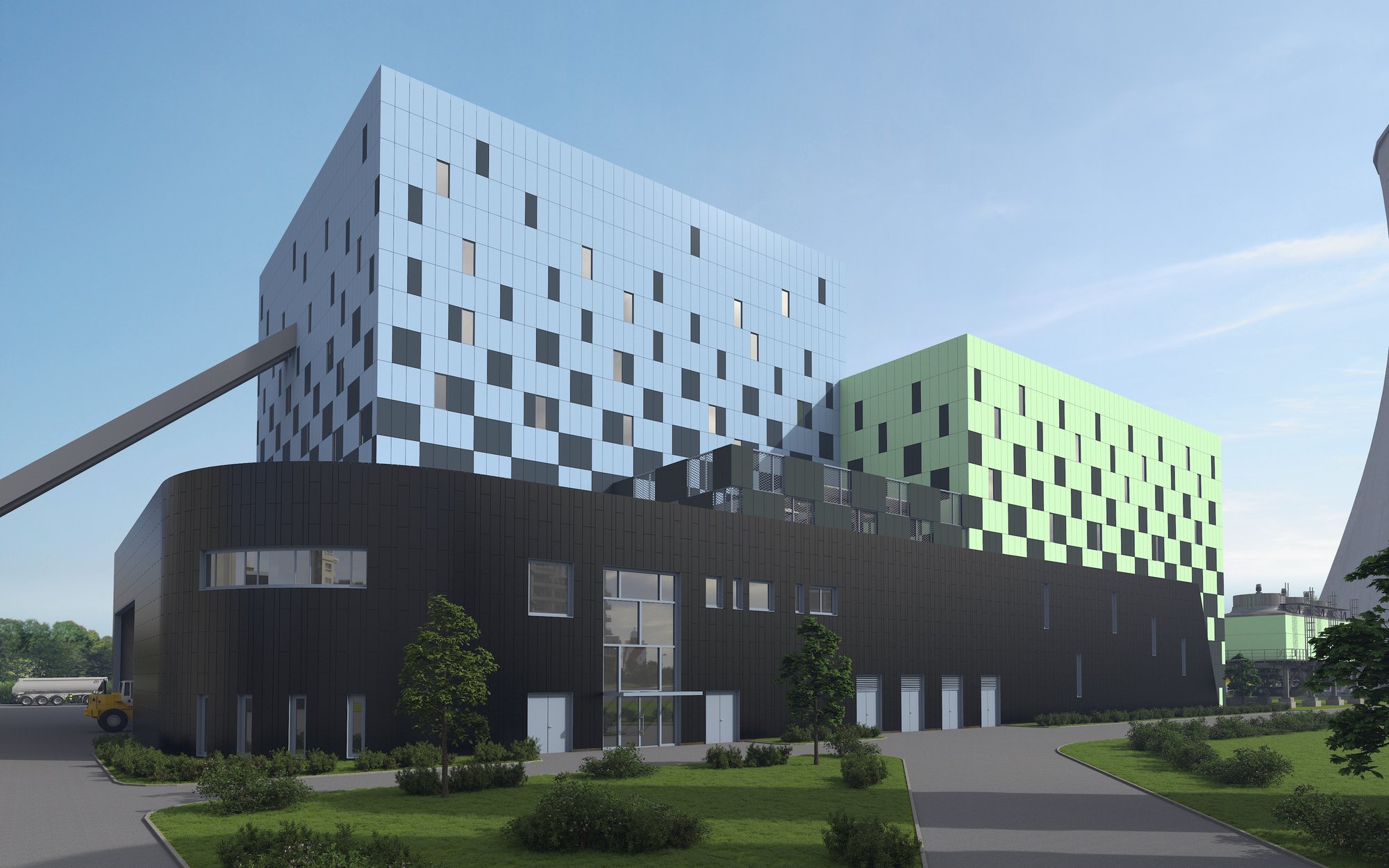

The project company BEH Bioenergie Hannover GmbH of Danpower GmbH, a subsidiary of enercity AG, is building a biomass power plant at the existing power plant site in Hannover-Stöcken. Standardkessel Baumgarte has been awarded the contract as general contractor for the supply, construction and commissioning of the entire plant technology for the CHP plant. The biomass power plant is to utilise approx. 200,000 tonnes of non-recyclable waste wood per year. With a combustion heat output of 90 MW, the power plant will feed up to 19 MW of electrical energy into the power grid and, with a correspondingly reduced electrical output, provide up to 80 MWth of heat to supply enercity's district heating customers.

THE SOLUTION

A proven air-cooled SBG pusher-type grate is used as the firing system. The SBG pusher-type grate offers decisive advantages with regard to the composition and range of waste wood fuels to be used. The design of the entire plant allows a very high degree of flexibility in order to meet all possible operating requirements. In addition to almost any combination of electricity and heat generation, the plant can also be operated with pure electricity generation or pure heating generation.

In pure heating mode, the plant can extract a maximum of 89 MW of heat with a fuel utilisation ratio of almost 100 %. This is made possible by the planned flue gas condensation, which exploits the calorific value effect. The condensation heat of the moisture contained in the flue gas is made usable for district heating through the use of an absorption heat pump.

For more information, please see our reference sheet.

"Thanks to our broad product portfolio in the field of biomass firing systems, we can always offer our customers an optimal solution"

Olaf Schumacher

Head of Sales

Technical Data

Waste Wood A3 - A4

Nominal13.0 MJ/kg

Maximal16.0 MJ/kg

Minimal10.0 MJ/kg

Nominal25.0 t/h

Max.90 MW

Max.19 MW

102 t/h

461 °C

71 bar

Nominal150,690 m³/h i.N.

wit FG Cond.60 °C

17. BImSchV

Natural Circulation

2024

Discover more references from the biomass sector, from partial components to complex complete plants and operation & maintenance solutions.